Boost Your Devices: Discover Premium Komatsu Undercarriage Parts Solutions

Boost Your Devices: Discover Premium Komatsu Undercarriage Parts Solutions

Blog Article

Explore Undercarriage Components for Your Equipment Requirements

Keeping the undercarriage of your machinery is a crucial aspect frequently overlooked until concerns arise. From excavators to bulldozers, the undercarriage plays a vital function in the total efficiency and longevity of hefty tools. Understanding the parts that compose the undercarriage and the significance of selecting the right components is key to making sure smooth procedures and cost-efficient maintenance. As we discover the globe of undercarriage components for equipment demands, a much deeper insight right into the ins and outs of this crucial system will certainly unfold, clarifying the structure that supports the performance of your tools.

Value of Undercarriage Maintenance

Routine upkeep of undercarriage parts is crucial for guaranteeing optimal performance and longevity of equipment. The undercarriage of heavy devices, such as excavators, excavators, and track loaders, plays an important function in sustaining the weight of the maker, offering stability on numerous terrains, and permitting for smooth operation - komatsu undercarriage parts. Disregarding undercarriage maintenance can result in costly repair services, decreased performance, and possible safety threats

Routine evaluations of undercarriage parts, such as track chains, rollers, idlers, and gears, are vital to determine wear and tear beforehand. Attending to problems immediately can protect against more damage to the undercarriage and other components of the equipment. Proper cleaning of undercarriage components is likewise needed to remove dust, debris, and other contaminants that can increase wear and corrosion.

Routine lubrication of undercarriage components is another essential facet of maintenance to make sure smooth movement and minimize friction in between elements. In addition, tracking the usage hours and keeping maintenance documents can assist in scheduling timely substitutes and lengthening the total life expectancy of the equipment. By prioritizing undercarriage upkeep, equipment proprietors can optimize performance, minimize downtime, and eventually save money on repair service expenses in the long run.

Types of Undercarriage Components

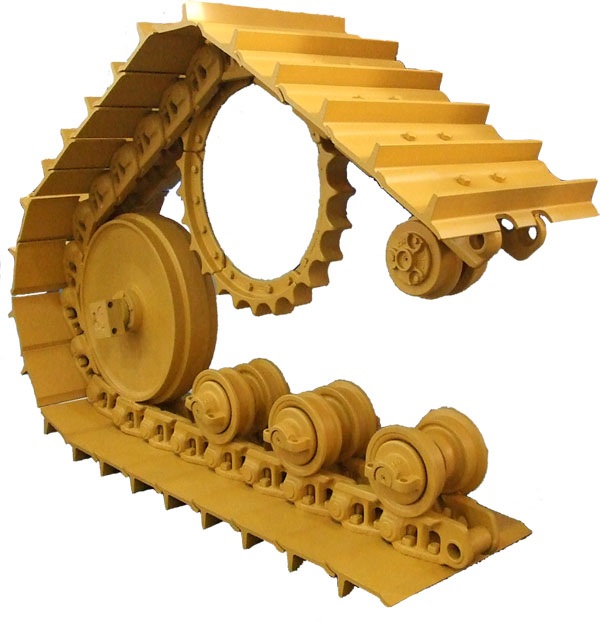

Maintenance of undercarriage parts is necessary for equipment durability; understanding the different sorts of undercarriage parts is important for efficient maintenance techniques. Undercarriage parts differ depending upon the kind of machinery and its designated use. Common kinds of undercarriage components consist of track chains, track shoes, rollers, idlers, gears, and track frameworks.

Track chains are accountable for propelling the equipment onward and supporting the weight of the tools. Track shoes provide traction and secure the track chain from wear and tear. Rollers assist in weight circulation and track assistance, while idlers aid preserve appropriate track tension. Gears involve with the track chain and transfer power to relocate the equipment. Track frameworks offer as the structure for the entire undercarriage assembly, connecting all the elements together.

Routine examination and upkeep of these undercarriage components are important to stop pricey fixings and downtime. By understanding the function of each type of undercarriage part, machinery operators can guarantee ideal performance and prolong the life expectancy of their devices.

Aspects to Think About When Picking Components

An additional essential variable is compatibility with the certain machinery model. Each piece of machinery might have distinct needs for undercarriage components, consisting of size, design, and specs. Guaranteeing that the components are compatible with the equipment will assist prevent functional issues and premature wear.

In addition, it is important to think about the operating problems in which the machinery will certainly be made use of. Factors such as surface, weather, and use frequency can all influence the deterioration on undercarriage components. Selecting components that are made to withstand the particular operating problems can help extend the life of the equipment and minimize upkeep prices in the lengthy run.

Advantages of High-Quality Undercarriage Components

Top quality undercarriage parts play a vital duty in boosting equipment efficiency and expanding its operational longevity. By buying superior undercarriage parts, equipment operators benefit from enhanced longevity and reliability. Among the key advantages of making use of high-quality undercarriage parts is improved efficiency. These components are made to stand up to heavy lots, extreme surfaces, and requiring working problems, making sure that the machinery runs at its ideal degree without constant break downs or malfunctions.

Moreover, premium undercarriage parts add to cost financial savings in the long run. While the preliminary financial investment might be higher compared to standard components, the resilience and durability of costs components decrease the need for regular replacements and repairs. This not only reduces downtime yet likewise decreases maintenance costs, ultimately resulting in greater total efficiency and earnings for services that count on hefty equipment.

In addition, exceptional undercarriage components enhance safety by reducing the threat of unexpected failures or accidents. The raised stability and efficiency provided by top notch elements develop a more secure working setting for equipment drivers and those operating in close proximity to the tools. Eventually, picking high-grade undercarriage parts is a strategic choice that produces various advantages browse around this web-site in terms of performance, long life, cost-efficiency, and security.

Tips for Extending Undercarriage Life Expectancy

To make best use of the durability of undercarriage components for equipment, executing positive treatment methods is important for making sure optimal performance and sturdiness. Regularly evaluating the undercarriage look at here parts for indications of deterioration, such as worn-out tracks, loose screws, or harmed rollers, is vital. Attending to these concerns quickly can prevent additional damages and expand the life-span of the undercarriage. Furthermore, maintaining correct track tension is crucial to lower early wear on the components. Over-tightened tracks can lead to raised anxiety on the undercarriage, while loose tracks can create misalignment and uneven wear.

Running the equipment within suggested guidelines, such as avoiding extreme speeds or overloading, can likewise add to prolonging the undercarriage life expectancy. By complying with these ideas, machinery owners can ensure optimal performance and resilience of their undercarriage components.

Verdict

Finally, maintaining the undercarriage parts of machinery is crucial for optimal efficiency and long life. By understanding the various kinds of undercarriage parts and factors to think about when selecting them, organizations can ensure their tools runs effectively. Investing in top quality undercarriage parts not only improves efficiency yet also minimizes downtime and pricey repair work. By complying with proper upkeep techniques, services can prolong the life-span of their undercarriage components, ultimately conserving time and cash in the future.

Normal upkeep of undercarriage parts is critical for ensuring optimum efficiency and longevity of equipment.Maintenance of undercarriage parts is crucial for machinery durability; comprehending the various kinds of undercarriage components is important for reliable upkeep techniques.When picking undercarriage components for machinery, it is essential to think about different aspects to make sure optimal efficiency and long life.To maximize the long life of undercarriage components for equipment, executing aggressive treatment practices is important for guaranteeing ideal performance and find out longevity. By complying with these ideas, machinery proprietors can guarantee optimal performance and resilience of their undercarriage components.

Report this page